Fat Facts

Episode 1: May 2025

How Yeast Makes Beauty-Grade Oils, a Q&A with Dr. José Miguel Laplaza

Written by Joanna Bundus, PhD

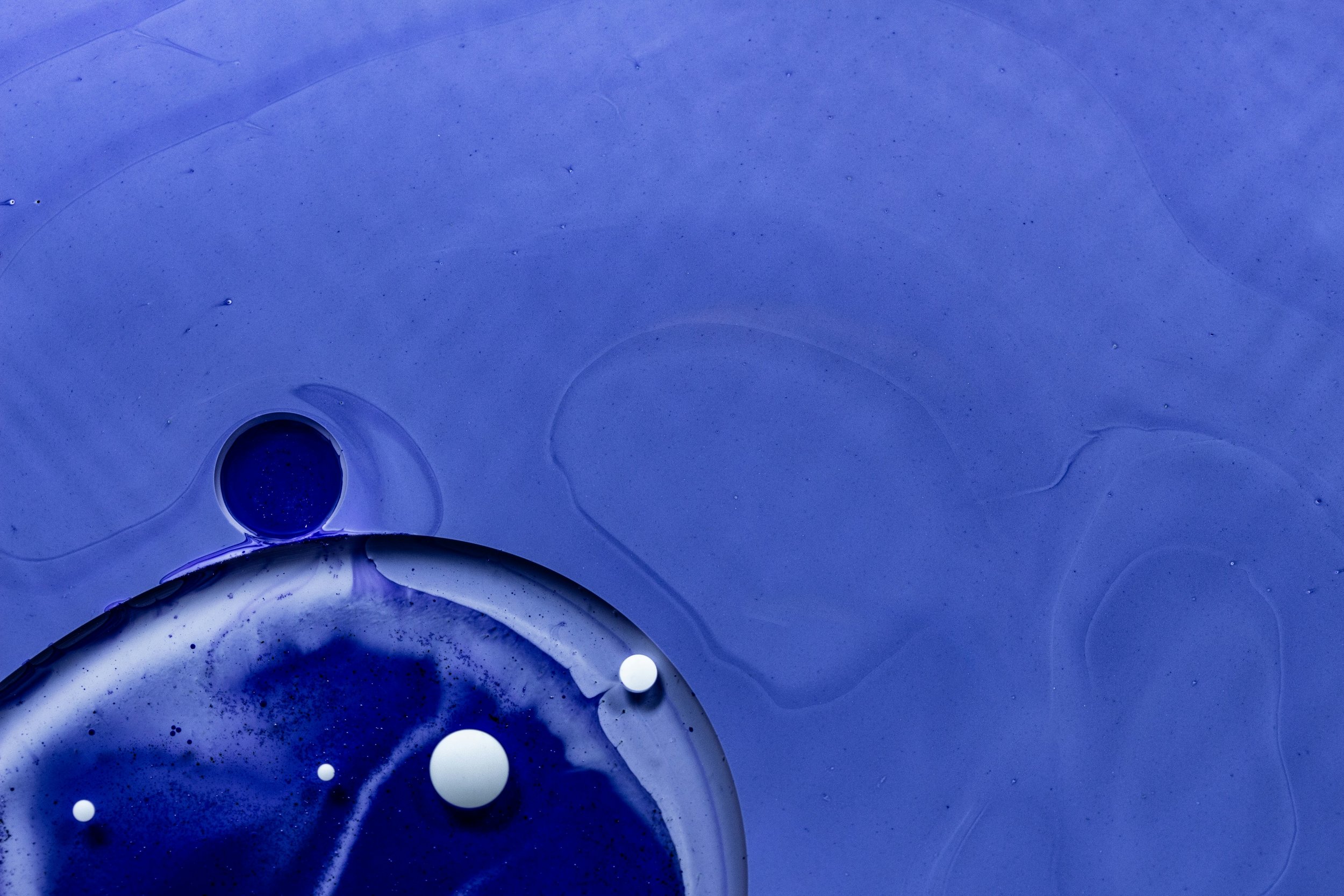

Image description: The cells in the top image are at the beginning of the fermentation process. The cells in the bottom image are at the end of the fermentation process; the cells are full of oil.

Key takeaways

Fermentation enables consistency. Precision-controlled processes deliver reliable ingredient quality, minimizing batch-to-batch variation common in plant-derived oils

Microbial oils support future-facing formulations. Custom lipids can be created to meet emerging needs—like enhanced spreadability, structured textures, or occlusivity—while aligning with clean beauty standards

Cleaner label, higher traceability. Fermentation-derived ingredients support transparency, are traceable to a single source, and can avoid common allergens and contaminants.

Strain design shapes functionality. Through metabolic engineering, the fatty acid composition of microbial oils can be tailored to match or improve upon natural oils like palm, shea, or coconut.

Using precision fermentation and our microbe, Lipomyces starkeyi, we produce premium fats designed for beauty formulations. But how does a single-celled organism make oil, and how do we turn that into a functional cosmetic ingredient? To answer these questions, we spoke with Dr. José Miguel Laplaza, Xylome’s Principal Scientist.

Q: Do yeasts make oil naturally?

Dr. Laplaza: Yes. Specific yeasts are oleaginous (oil-producing) because they can naturally accumulate large amounts of lipids when grown under the right conditions. Typically, this occurs when carbon is abundant and nitrogen is limited. These lipids are stored inside the cells as lipid bodies. Our unique strain, Lipomyces starkeyi, is particularly efficient and can store up to 80% of its dry weight as oil. This makes it an outstanding foundation for scalable, fermentation-driven lipid manufacturing.

Q: What kind of oils have we created so far?

Dr. Laplaza: Yoil® P is our first launch. It’s a biomimetic RBD palm oil, offering a cleaner and more sustainable alternative to Elaeis guineensis, rich in palmitic acid (C16:0) and oleic acid (C18:1), providing a creamy texture and excellent skin feel. It’s solid at room temperature but softens and spreads easily on skin contact. This profile is compatible with a range of emulsions, anhydrous formats, and surfactant-free systems. It is suitable for formulations like balms, cleansing bars, and oil-based creams where sensory feel and melting behavior matter most.

Q: How do you get the yeast to make more oil?

Dr. Laplaza: We use metabolic engineering, essentially redirecting the yeast’s metabolism so more of the carbon from sugars ends up as fat. This involves making changes that boost lipid synthesis pathways and block pathways that break down. We have also made genetic changes that modify the fatty acid profile, producing a more saturated lipid and a more solid fat at room temperature. Equally crucial, however, is dialing in the fermentation conditions. We’ve invested extensive effort in fine-tuning variables such as feeding schedule, media composition, and cultivation temperature. Our strain is free from foreign genes and produced under food-grade GMP conditions, giving formulators confidence in safety and purity.

Q: What does the fermentation process look like?

Dr. Laplaza: Imagine a craft brewery — but instead of brewing beer, we're brewing structured oils designed for high-performance cosmetics. We use aerobic bioreactors to feed sugar-based substrates and carefully manage oxygen transfer, pH, and nutrient levels. Over time, the yeast shifts from biomass growth to lipid accumulation mode as the nutrients required for growth become limited. When the fermentation is complete, we harvest the biomass and extract the oil.

Q: What makes this type of oil valuable in beauty products?

Dr. Laplaza: Yoil® P is solid at room temperature, melts on skin, and is white with a clean, neutral scent. It blends well with essential oils and active ingredients. Yoil offers occlusivity without greasiness and supports viscosity structuring in emulsions. Additionally, it helps improve spreadability and melt profile in solid formats. Because it’s made with fermentation, it’s highly consistent, traceable, and scalable. That makes Yoil® P an ideal drop-in replacement for RBD palm oil, helping brands make an easy and sustainable swap for those who love the benefits and functionality of palm oil.

Closing thoughts

Dr Laplaza: We’re just scratching the surface of what microbial oils can do. As we further optimize our process and continue fine-tuning lipid profiles for different functions, we see real opportunities to design fats for specific formulations. We look forward to collaborating with formulators and partners to test these premium fats and oils in their products and steer the development of even more functional oils to their specific needs.

Bio: Dr. José Miguel Laplaza is Principal Scientist at Xylome, where he leads research and development of yeast-based processes to produce lipids for beauty and personal care. With over 20 years of experience in metabolic engineering and industrial biotechnology, Dr. Laplaza specializes in optimizing biological systems for high-performance ingredient production. He holds a Ph.D. Genetics from the University of California, Davis, and has held scientific leadership roles at Levadura Bio, Verdezyne, and Cargill.

Keep Exploring

The future of oil.

510 Charmany Dr. Ste 61

Madison, WI 53719

Sitemap

© Xylome Corporation 2024